- single stage centrifugal pumps with bearing housing

- monoblock stage pumps

- process and chemical pumps

- self priming pumps

- multistage vertical and horizontal pumps

- shaft pumps

- diagonal pumps

- dual pump

- submersible pumps

- Franklin Electric submersible motors

- Sanitary pumps Grundfos Hilge

- deep-sea pumps

- mixing spotlight

- vacuum pumps blowers

- screw pumps

- hydrotransport pumps

- sets Hydrophore

- metering pumps and dosing systems

- water supply machines

- linear monoblock pumps

- Circulation pumps

- stampings

- self priming dewatering pumps with electric and internal combustion

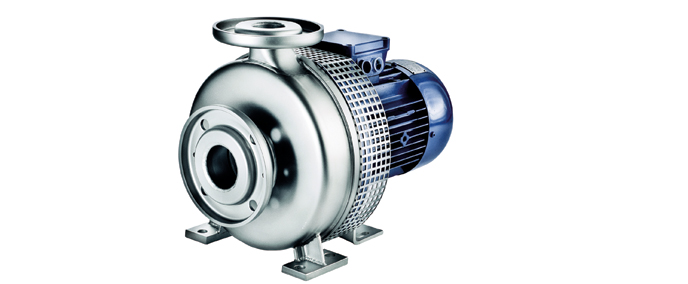

Sanitary pumps Grundfos Hilge

Description

Sanitary pumps are made of stainless steel mainly due to its use in breweries, beverage production plants, dairies, food, pharmaceutical, biotech, cosmetic, water treatment plants, semiconductor manufacturing factories and textile industry.

Sanitary pumps designed according to strict hygiene criteria. By appropriate finish material which is the most important physical properties of the pump, the growth of bacteria and germs are excluded.

Therefore, the sanitary pump range consists of many different types, each device will ideally suited to the particular installation conditions.

Technical data

Euro-HYGIA – single sanitary pumps with axial inlet

| efficiency | lifting height | operating pressure | diameter DN | engine power | operating temperature |

|---|---|---|---|---|---|

| to 108 m3/h | to 70 m | 1,6 MPa | 25 - 125 | 0,55 kW to 22 kW | 95 °C (150 °C on order) |

CONTRA – single-and multi-stage sanitary pumps with suction pumps

| efficiency | lifting height | operating pressure | diameter DN | engine power | operating temperature |

|---|---|---|---|---|---|

| to 55 m3/h | to 160 m | 2,5 MPa | 25 - 80 | 0,55 kW to 18,5 kW | 95 °C (150°C on order) |

SIPLA – single-stage, self-priming side channel sanitary pumps

| efficiency | lifting height | operating pressure | diameter DN | engine power | operating temperature |

|---|---|---|---|---|---|

| to 80 m3/h | to 56 m | 1 MPa | 32 - 80 | 0,55 kW to 22 kW | 95°C |

MAXA – single process pump to the axial inlet of a stainless steel

| efficiency | lifting height | operating pressure | diameter DN | engine power |

|---|---|---|---|---|

| to 820 m3/h | to 97 m | 1 MPa | 80 - 150 | 7,5 kW to 90 kW |

MAXANA – single process pump to the axial inlet of a stainless steel

| efficiency | lifting height | operating pressure | diameter DN | engine power |

|---|---|---|---|---|

| to 165 m3/h | to 97 m | 1 MPa | 32 - 80 | 2,2 kW to 55 kW |

DURIETTA – single-or multistage, end-suction sanitary

| efficiency | lifting height | operating pressure |

|---|---|---|

| to 6 m3/h | to 70 m | 0,8 MPa |

Contact with us

You may also like:

sets Hydrophore

Sets hydrophore are built based on one or more pumps: vertical multistage centrifugal, horizontal, single stage, linear, deep-sealed in airtight coats. They are offered as complete sets of pumps connected in parallel with the collector and fittings (stainless steel or carbon zinc), equipped with control systems and monitoring work. Booster is designed for pumping and improve water pressure in water supply systems, hydrant systems, residential, office and public buildings and industrial installations.

deep-sea pumps

Deep-sea pumps are designed for pumping of potable water, treated water, raw, sea, mineral and thermal water without containing abrasive admixtures and fibers. Depending on the type of submersible pump sand content can be up to 50-100g/m3. Submersible pumps are used in water supply for drinking and personal shots of water and drainage systems of different industries. They are mounted mainly in borehole wells with known parameters (yield wells and dynamic water table).

mixing spotlight

Gravels, mixers and aeration ejectors are mainly used for mixing and aeration of sewage in order to among others: prevention of sedimentation and separation of layers, support processes, harmonizing physicochemical properties of factor and production of fluid movement in reservoirs. These devices are used in sewage treatment plants, septic catchments, but also in the joints and the food industry.