- single stage centrifugal pumps with bearing housing

- monoblock stage pumps

- process and chemical pumps

- self priming pumps

- multistage vertical and horizontal pumps

- shaft pumps

- diagonal pumps

- dual pump

- submersible pumps

- Franklin Electric submersible motors

- Sanitary pumps Grundfos Hilge

- deep-sea pumps

- mixing spotlight

- vacuum pumps blowers

- screw pumps

- hydrotransport pumps

- sets Hydrophore

- metering pumps and dosing systems

- water supply machines

- linear monoblock pumps

- Circulation pumps

- stampings

- self priming dewatering pumps with electric and internal combustion

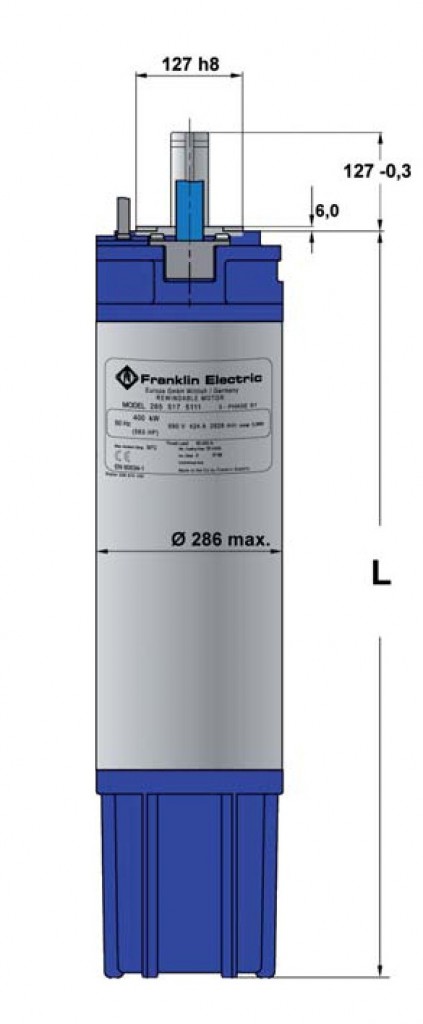

Franklin Electric submersible motors

Technical data

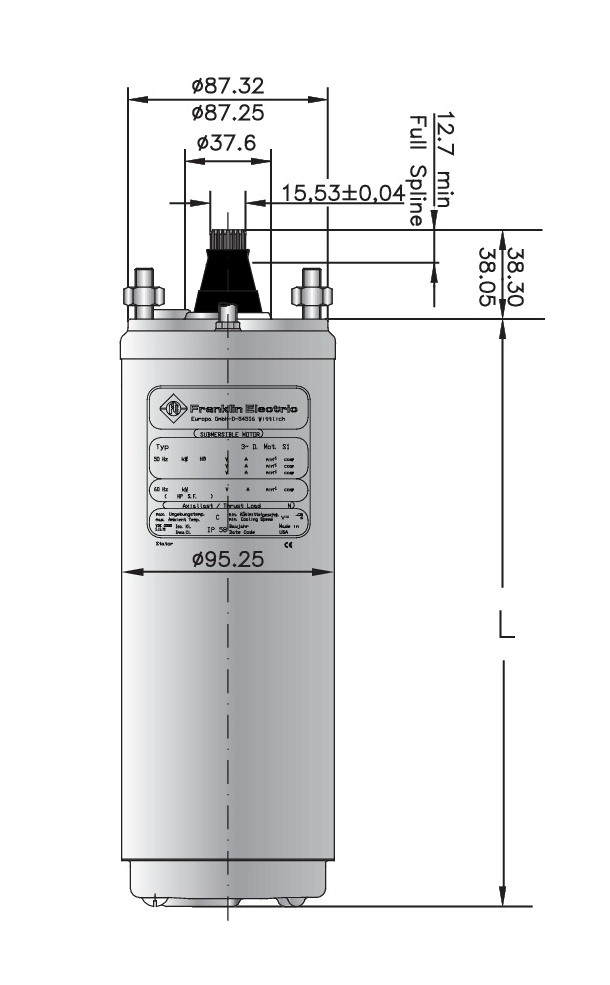

4″ submersible motors

| motors | quality in wells | advantages | standard | options |

|---|---|---|---|---|

| 4″ submersible motors Franklin Electric | are manufactured in ISO 9001. They are designed to work in wells section 4 "or greater. They are filled with water and liquid FES93 lubricating thrust bearings and thrust, which makes them maintenance-free operation. Liquid FES93 allows storage at ambient temperature to -40°C | - Flooded hermetically stator. increased opportunity for heat dissipation to the outside. - Highest quality electrical performance (low operating costs, low temperature of the windings) - interchangeable connector outer conductor "Water-Bloc ™" - the material from which made cables are compliant with the standards for drinking water (KTW approved) - water lubricated thrust bearing and thrust - all engines filled the factory, 100% tested - construction does not cause pollution, filled with liquid FES93 | ||

| 4″ PCS 1-phase | produced in standard and under pain of ISO 9001 procedures. | -Flooded hermetically stator. increased opportunity for heat dissipation to the outside. - Highest quality electrical performance (low operating costs, excellent cooling coils) - interchangeable connector outer conductor "Water-Bloc ™" - material from któergo made cables are compliant with the standards for drinking water (KTW approved) - water lubricated thrust bearing and thrust - all motors prefilled, 100% tested - construction does not cause pollution, filled with liquid FES93. | - Capacity 0,25 - 2,2 kW-voltage 220 - 230 V / 50 Hz-emphasis on the thrust bearing 3/4 Kn-start with external capacitor | - Motor cable 1.5 m in conformity with VDE, KTW-on request available in other lengths-built firewall przeciwpiorunowa-built-in surge protection (0.25 .... 1.5 kW) |

| 4″ 2-wire 1-phase | - manufactured in ISO 9001 are designed for direct connection to a single phase power supply without the use of starter box or capacitor. The electronic system raises winding starter to start the engine. Built-in are also przeciwpiorunowe and overload protection. Automatic reverse torque in the case of contamination of the pump ensures a long maintenance-free operation and low cost of installation. | - Flooded hermetically stator. increased opportunity for heat dissipation to the outside. - Water-lubricated thrust bearing and thrust - made of steel corrosion in AISI 304 SS - interchangeable connector outer conductor "Water-Bloc ™" - design does not cause pollution, filled with liquid FES93 - the highest quality electrical performance (low operating costs) - Low temperature of the windings - automatic reverse torque when starting the engine - the material from któergo made cables are compliant with the standards for drinking water (KTW approved) | - Capacity 0,37 - 1,1 kW-voltage 220 - 230 V / 50 Hz-emphasis on the thrust bearing 1500N, 3000N, 4000N-direct medium to connect to the network without the use of starter box-built motor protection | |

| 4″ 3-wire | - are manufactured in ISO 9001. They are designed to work in wells section 4 "or greater. They are filled with water and liquid FES93 lubricating thrust bearings and thrust, which makes them maintenance-free operation. Liquid FES93 allows storage at ambient temperature to -40. The special membrane provides pressure compensation in the engine. Single-phase three-wire motors are designed to work with boot box manufacturing Franklin Electric, in which there are two starting capacitors. This provides maximum torque at start-up of single-phase motors | - Flooded hermetically stator. increased opportunity for heat dissipation to the outside. - Highest quality electrical performance (low operating costs, low temperature of the windings) - interchangeable connector outer conductor "Water-Bloc ™" - material from któergo made cables are compliant with the standards for drinking water (KTW approved) - water lubricated thrust bearing and thrust - all engines filled the factory, 100% tested - construction does not cause pollution, filled with liquid FES93 - the biggest torque of all single-phase motors - cooperation with boot box with two capacitors starter | - 0.25 - 2.2 kW / 220 - 230 V / 50 Hz 2.2 - 3.7 kW / 220 - 230 V / 50 Hz version-emphasis on the thrust bearing 3000N, 4000N, 6500N-requires the use of box boot with two capacitors | - Motor cable comply with VDE / KTW - 1.5 m High Thrust-bearing other cable lengths available-built surge protection-in execution engine stainless steel 316 SS applied seal SiC |

| 4″ 3-wire | - are manufactured in ISO 9001. They are designed to work in wells section 4 "or greater. They are filled with water and liquid FES93 lubricating thrust bearings and thrust, which makes them maintenance-free operation. Liquid FES93 allows storage at ambient temperature to -40°C | - Flooded hermetically stator. increased opportunity for heat dissipation to the outside. - Highest quality electrical performance (low operating costs, low temperature of the windings) - interchangeable connector outer conductor "Water-Bloc ™" - the material from which made cables are compliant with the standards for drinking water (KTW approved) - water lubricated thrust bearing and thrust - all engines filled the factory, 100% tested - construction does not cause pollution, filled with liquid FES93. |

- 0,37 - 3,0 kW / 220 - 230 V / 50 Hz-0.37 - 3.0 kW / 380 - 415 V / 50 Hz-0.37 - 3.0 kW / 500 V / 50 Hz 2.2 - 5.5 kW / 220 - 230 V / 50 Hz version of High Thrust-bearing 2,2 - 7,5 kW / 380 - 415 V / 50 Hz version of High Thrust-bearing 2,2 - 7.5 kW / 500 V / 50 Hz version of High thrust-bearing pressure on the thrust bearing 3000N, 4000N, 6500N | - Motor cable comply with VDE / KTW - 1.5 and 2.5 m-other cable lengths available-in execution engine stainless steel 316 SS applied seal SiC |

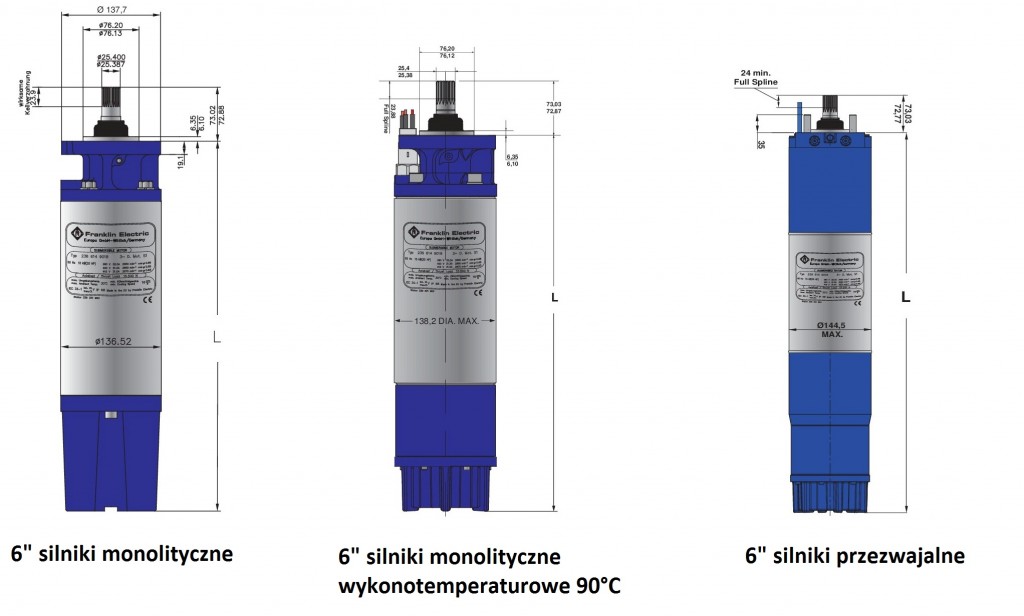

6″ submersible motors

| motors | quality in wells | advantages | standard | options |

|---|---|---|---|---|

| 6″ Franklin Electric submersible motors | - are manufactured in ISO 9001. They are designed to work in wells with section 6 "or larger. They are filled with water and liquid FES93 lubricating thrust bearings and thrust, causing their long and trouble-free operation. Fluid FES93 allows storage at ambient temperature to-15oC. Special membrane provides compensation pressure inside the engine. standard mechanical seal is used type SiC. | - Flooded hermetically stator. increased opportunity for heat dissipation to the outside. - Highest quality electrical performance (low operating costs, low temperature of the windings) - Interchangeable connector outer conductor "Water-Bloc ™" - The material from which made cables are compliant with the standards for drinking water (approved by KTW) - Water-lubricated thrust bearing and thrust - All engines filled the factory, 100% tested - Construction does not cause pollution, filled with liquid FES93. |

||

| 6″ submersible motors Hi Temp 90 | - are manufactured in ISO 9001 is a quality drives for submersible pumps designed for use in wells with section 6 "or larger. They are filled with water and liquid FES93 lubricating thrust bearings and thrust, which makes them maintenance-free operation. A special diaphragm ensures pressure compensation in the engine. fluid FES93 allows storage at ambient temperature to-15oC | - Nominal ambient temperature - 90 ° C - Increase engine performance over the medium temperature 30 ° C. - Required cooling flow 0 cm / s in the larger wells for medium temperature below 30 ° C. - Interchangeable connector outer conductor "Water-Bloc ™" - The material from which made cables are compliant with the standards for drinking water (approved by KTW) - Engine "Sand Fighter" SiC shaft seal for high durability in sandy environments - Supply pipes made of materials resistant to high temperatures - Electrical design of high efficiency and low operating costs - All engines filled the factory, 100% tested - Construction does not cause pollution, filled with liquid FES93 |

- 3.7 ... 30kW - 6 "NEMA flange - Degree of protection IP68 - Switching: Up to 20x / h. - Installation position: vertical / horizontal - Voltage tolerance: +6% / -10% UN - Insulation: Class F - Start: DOL, star-triangle - Cooling flow: min. 16 cm / s - Ambient temperature: 90 ° C - Emphasis on the thrust bearing 15.5 kN 27.5 kN |

- 500V, 1000V - Engine performance stainless steel 316 SS - Power cords of different lengths (Up to 45m) |

| 6″ | - are manufactured in ISO 9001 is a quality drives for submersible pumps designed for use in wells with section 6 "or larger. They are filled with water and liquid FES93 lubricating thrust bearings and thrust, which makes them maintenance-free operation. A special diaphragm ensures pressure compensation in the engine. fluid FES93 allows storage at ambient temperature to-15oC. | - Flooded hermetically stator. increased opportunity for heat dissipation to the outside. - 37 and 45kW - nominal ambient temperature - 50 ° C - Interchangeable connector outer conductor "Water-Bloc ™" - The material from which made cables are compliant with the standards for drinking water (approved by KTW) - Engine "Sand Fighter" SiC shaft seal for high durability in sandy environments - Electrical design of high efficiency and low operating costs - All engines filled the factory, 100% tested - Construction does not cause pollution, filled with liquid FES93 |

- 4 ... 45kW - 6 "NEMA flange - Degree of protection IP68 - Switching: Up to 20x / h. - Installation position: vertical / horizontal - Voltage tolerance: +6% / -10% UN - Insulation: Class F - Start: DOL, star-triangle - Cooling flow: min. 16 cm / s - Ambient temperature: 30 ° C (for motors up to 30kW), 50 ° C (for engines 37 and 45 kW) - Emphasis on the thrust bearing 15.5 kN 27.5 kN |

- 500V, 1000V - PT100 temperature sensor (sold separately) - Engine performance stainless steel 316 SS - Power cords of different lengths (Up to 50m) - Built-in temperature sensor PTC - Built-in SubMonitor Transmitter - Sensor overheating |

| 6" | - are manufactured in ISO 9001 is a quality drives for submersible pumps designed for use in wells with section 6 "or larger. They are filled with water and liquid FES93 lubricating thrust bearings and thrust, which makes them maintenance-free operation. A special diaphragm ensures pressure compensation in the engine. fluid FES93 allows storage at ambient temperature to-15oC. to work under aggressive medium (chlorides, temperature) available engines are made entirely of stainless 316SS or 904L. | - The material from which wywykonane cables are compliant with the standards for drinking water (approved by KTW) - Sand slinger and shaft seal design protects against dirt motor - Electrical design of high efficiency and low operating costs - All engines filled the factory, 100% tested - Storage temperature from-15oC to +60 oC - Design with replaceable sensor PTC - Thrust bearing type "Kingsbury" - Engine "Sand Fighter" SiC shaft seal for high durability in sandy environments - Construction does not cause pollution, filled with liquid FES93. |

- 4 ... 37kW - 6 "NEMA flange studs (M12) - Degree of protection IP68 - Switching: Up to 20x / h. - Installation position: vertical / horizontal - Voltage tolerance: +6% / -10% UN - Insulation: Class F - Start: DOL, star-triangle - Cooling flow: min. 20 cm / s for power 4 - 15kW 50 cm / s for Power 18.5 - 37kW - Ambient temperature: 30 ° C for winding with PVC insulation 50oC for winding insulation PE2/PA - Emphasis on the thrust bearing 15.5 kN 27.5 kN |

- 500V, 1000V - Engine performance stainless steel 316 or 904L SS - Power cords of different lengths (Up to 50m) |

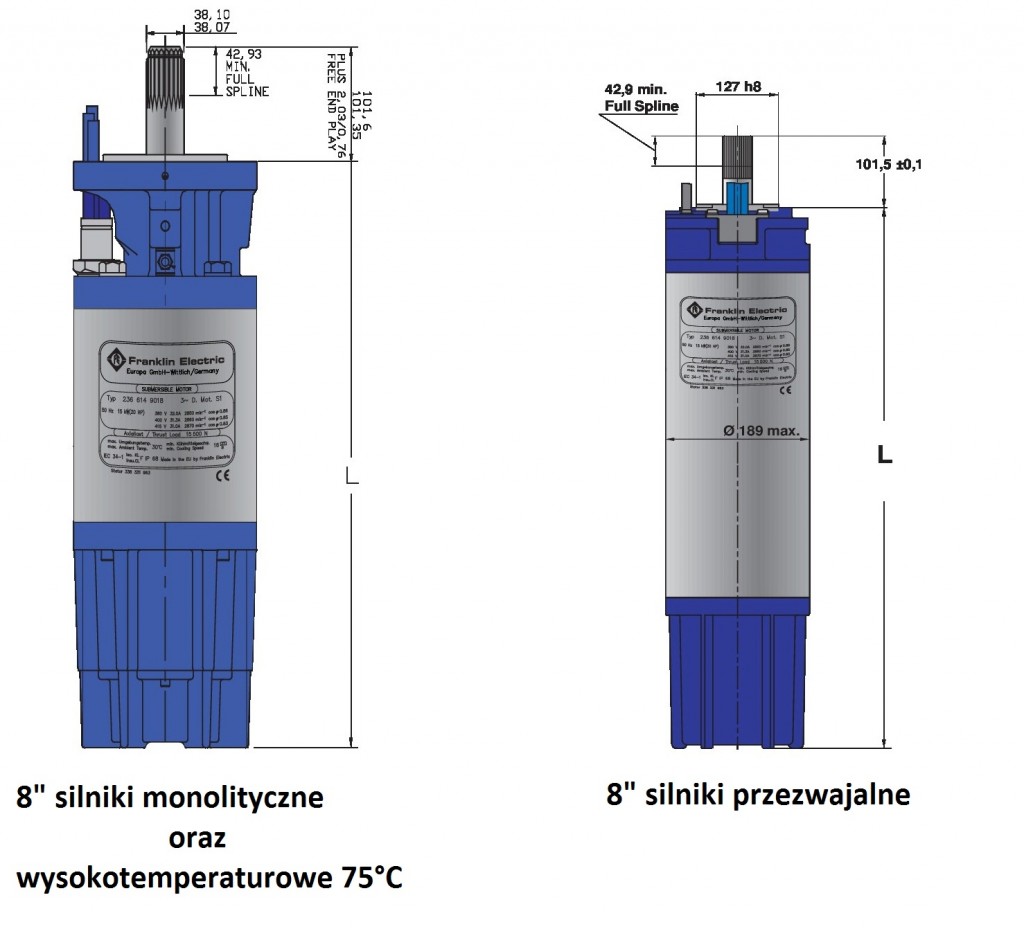

8″ submersible motors

| motors | quality in wells | advantages | standard | options |

|---|---|---|---|---|

| 8″ Franklin Electric submersible motors | are manufactured in ISO 9001. They are designed to work in wells with section 8 "or larger. They are filled with water and liquid FES93 lubricating thrust bearings and thrust, causing their long and trouble-free operation. Fluid FES93 allows storage at ambient temperature to-15oC. Special membrane provides compensation pressure inside the engine. standard mechanical seal is used type SiC. | - Flooded hermetically stator. increased opportunity for heat dissipation to the outside. - Highest quality electrical performance (low operating costs, low temperature of the windings) - Interchangeable connector outer conductor "Water-Bloc ™" - The material from which made cables are compliant with the standards for drinking water (approved by KTW) - Water-lubricated thrust bearing and thrust - All engines filled the factory, 100% tested - Construction does not cause pollution, filled with liquid FES93. |

||

| 8″ submersible motors Hi Temp 75 | are manufactured in ISO 9001 is a quality drives for submersible pumps designed for use in wells with section 8 "or larger for temperatures up to 75oC. They are filled with water and liquid FES93 lubricating thrust bearings and thrust, causing their long maintenance-free operation . a special diaphragm ensures pressure compensation in the engine. fluid FES93 allows storage at ambient temperature to-15oC. | - Nominal ambient temperature - 75 ° C. - Increase engine performance over the medium temperature 30 ° C. - Required cooling flow 0 cm / s in the larger wells for medium temperature below 30 ° C. - Interchangeable connector outer conductor "Water-Bloc ™" - The material from which made cables are compliant with the standards for drinking water (approved by KTW) - Engine "Sand Fighter" SiC shaft seal for high durability in sandy environments - Supply pipes made of materials resistant to high temperatures - Electrical design of high efficiency and low operating costs - All engines filled the factory, 100% tested - Construction does not cause pollution, filled with liquid FES93 |

- 30 ... 110kW - 8 "NEMA flange - Degree of protection IP68 - Switching: Up to 20x / h. - Installation position: vertical / horizontal - Voltage tolerance: +6% / -10% UN - Insulation: Class F - Start: DOL, star-triangle - Cooling flow: min. 16 cm / s - Ambient temperature: 75 ° C - Emphasis on the thrust bearing 45 kN |

- 500V, 1000V - Engine performance stainless steel 316 SS - Power cords of different lengths (Up to 45m) |

| 8″ | - are manufactured in ISO 9001 is a quality drives for submersible pumps designed for use in wells with section 8 "or larger. They are filled with water and liquid FES93 lubricating thrust bearings and thrust, causing their long maintenance-free operation. special membrane provides compensation pressure in the engine. fluid FES93 allows storage at ambient temperature to-15oC. | - Flooded hermetically stator. increased opportunity for heat dissipation to the outside. - Interchangeable connector outer conductor "Water-Bloc ™" - The material from which made cables are compliant with the standards for drinking water (approved by KTW) - Engine "Sand Fighter" SiC shaft seal for high durability in sandy environments - Electrical design of high efficiency and low operating costs - All engines filled the factory, 100% tested - Construction does not cause pollution, filled with liquid FES93. |

- 30 ... 150kW - 8 "NEMA flange - Degree of protection IP68 - Switching: Up to 20x / h. - Installation position: vertical / horizontal - Voltage tolerance: +6% / -10% UN - Insulation: Class F - Start: DOL, star-triangle - Cooling flow: min. 16 cm / s - Built-in sensor overheating Subtrol - Emphasis on the thrust bearing 45 |

- 500V, 1000V - PT100 temperature sensor (sold separately) - Engine performance stainless steel 316 SS - Power cords of different lengths (Up to 50m) |

| 8" | are manufactured in ISO 9001 is a quality drives for submersible pumps designed for use in wells with section 8 "or larger. They are filled with water and liquid FES93 lubricating thrust bearings and thrust, causing their long maintenance-free operation. special membrane provides compensation pressure in the engine. fluid FES93 allows storage at ambient temperature to-15oC. to work under aggressive medium (chlorides, temperature) are available engines made entirely of steel 316SS or 904L. | - The material from which wywykonane cables are compliant with the standards for drinking water (approved by KTW) - Sand slinger and shaft seal design protects against dirt motor - Electrical design of high efficiency and low operating costs - All engines filled the factory, 100% tested - Storage temperature from-15oC to +60 oC - Design with replaceable sensor PTC - Thrust bearing type "Kingsbury" - Engine "Sand Fighter" SiC shaft seal for high durability in sandy environments - Construction does not cause pollution, filled with liquid FES93. |

- 30 ... 93kW - 8 "NEMA flange - Degree of protection IP68 - Switching: Up to 20x / h. - Installation position: vertical / horizontal - Voltage tolerance: +6% / -10% UN - Insulation: Class F - Start: DOL, star-triangle - Cooling flow: min. 20 cm / s for the power of 30 - 52kW 50 cm / s for power 55 - 93kW - Ambient temperature: 30 ° C for winding with PVC insulation 50oC for winding insulation PE2/PA - Emphasis on the thrust bearing 45 kN |

- 500V, 1000V - Engine performance stainless steel 316 or 904L SS - Power cords of different lengths (Up to 50m) - PT100 temperature sensor (sold separately) |

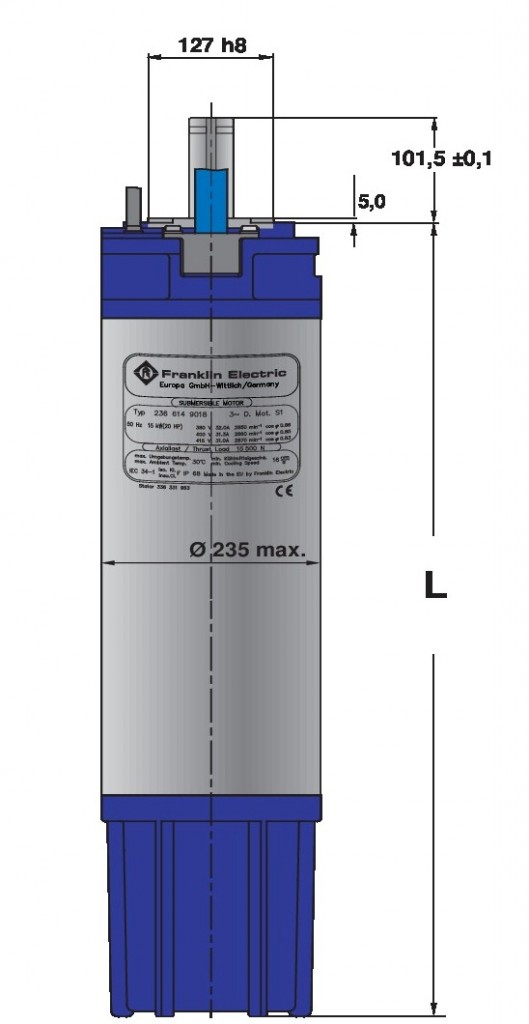

10″ submersible motorse

| motors | quality in wells | advantages | standard | options |

|---|---|---|---|---|

| 10″ Franklin Electric submersible motors | are manufactured in ISO 9001 is a quality drives for submersible pumps designed for use in wells with diameter of 10 "or larger. They are filled with water and liquid FES93 lubricating thrust bearings and thrust, causing their long maintenance-free operation. special membrane provides compensation pressure in the engine. fluid FES93 allows storage at ambient temperature to-15oC. to work under aggressive medium (chlorides, temperature) are available engines made entirely of steel 316SS or 904L. | - Easy to install with double flange - The material from which wywykonane cables are compliant with the standards for drinking water (approved by KTW) - Sand slinger and shaft seal design protects against dirt motor - Electrical design of high efficiency and low operating costs - All engines filled the factory, 100% tested - Storage temperature from-15oC to +60 oC - Design with replaceable sensor PTC - Thrust bearing type "Kingsbury" - Engine "Sand Fighter" SiC shaft seal for high durability in sandy environments - Construction does not cause pollution, filled with liquid FES93. |

- 85 ... 185kW - 10 "collar - Degree of protection IP68 - Switching: Up to 10x / h. - Installation position: vertical / horizontal - Voltage tolerance: +6% / -10% UN - Insulation: Class F - Start: DOL, star-triangle - Cooling flow: min. 50 cm / s - Ambient temperature: 30 ° C for winding with PVC insulation 45 ° C for winding insulation PE2/PA - Emphasis on the thrust bearing 60 kN |

- 500V, 1000V - Engine performance stainless steel 316 or 904L SS - Power cords of different lengths (Up to 50m) - PT100 temperature sensor (sold separately) |

12″ submersible motors

| motors | quality in wells | advantages | standard | options |

|---|---|---|---|---|

| 12″ Franklin Electric submersible motors | are manufactured in ISO 9001 is a quality drives for submersible pumps designed for use in wells with section 12 "or larger. They are filled with water and liquid FES93 lubricating thrust bearings and thrust, causing their long maintenance-free operation. special membrane provides compensation pressure in the engine. fluid FES93 allows storage at ambient temperature to-15oC. to work under aggressive medium (chlorides, temperature) are available engines made entirely of steel 316SS or 904L. | - Easy to install with double flange - The material from which made cables are compliant with the standards for drinking water (approved by KTW) - Sand slinger and shaft seal design protects against dirt motor - Electrical design of high efficiency and low operating costs - All engines filled the factory, 100% tested - Storage temperature from-15oC to +60 oC - Design with replaceable sensor PTC - Thrust bearing type "Kingsbury" - Engine "Sand Fighter" SiC shaft seal for high durability in sandy environments - Construction does not cause pollution, filled with liquid FES93. |

- 185 ... 400kW - 12 "collar - Degree of protection IP68 - Switching: Up to 5x / h. - Installation position: vertical / horizontal - Voltage tolerance: +6% / -10% UN - Insulation: Class F - Start: DOL, star-triangle - Cooling flow: min. 50 cm / s - Ambient temperature: 30 ° C for winding with PVC insulation - Emphasis on the thrust bearing 60 kN |

- 500V, 1000V - Engine performance stainless steel 316 or 904L SS - Power cords of different lengths (Up to 50m) - PT100 temperature sensor (sold separately) - Thrust bearing strength of 80 kN |

Additional files to download

You may also like:

mixing spotlight

Gravels, mixers and aeration ejectors are mainly used for mixing and aeration of sewage in order to among others: prevention of sedimentation and separation of layers, support processes, harmonizing physicochemical properties of factor and production of fluid movement in reservoirs. These devices are used in sewage treatment plants, septic catchments, but also in the joints and the food industry.

stampings

Stamping will help minimize the risk of clog hydraulic pumps, which occurs particularly in wastewater pumping systems because they contain solids. The use of pumping stations for the separation troublesome elements (strings, rags, bandages, etc.) can effectively avoid the problems in wastewater pumping systems – mainly the state of emergency pumping. Presses are ideal for pumping high-intensity range of sewage, sewage systems, which are dragged materials (such as hospitals, hotels), as well as in places where high lift is required.

screw pumps

Screw pumps are used when pumping liquids and slurries with high density and viscosity, containing solids. Can pump: caustic soda, lime milk, flotation sludge, sludge in wastewater treatment sludge from electroplating, pulp, ceramic, polymers, turbine oils, used oil motor and machine, edible oils, vegetable and fruit purees, cheese, yogurt. These pumps, available with variable speed, can be used as feeders in the industry: chemical, petrochemical, pulp and paper, wastewater, fatty, food, pharmaceutical, ceramic, beverage.