- single stage centrifugal pumps with bearing housing

- monoblock stage pumps

- process and chemical pumps

- self priming pumps

- multistage vertical and horizontal pumps

- shaft pumps

- diagonal pumps

- dual pump

- submersible pumps

- Franklin Electric submersible motors

- Sanitary pumps Grundfos Hilge

- deep-sea pumps

- mixing spotlight

- vacuum pumps blowers

- screw pumps

- hydrotransport pumps

- sets Hydrophore

- metering pumps and dosing systems

- water supply machines

- linear monoblock pumps

- Circulation pumps

- stampings

- self priming dewatering pumps with electric and internal combustion

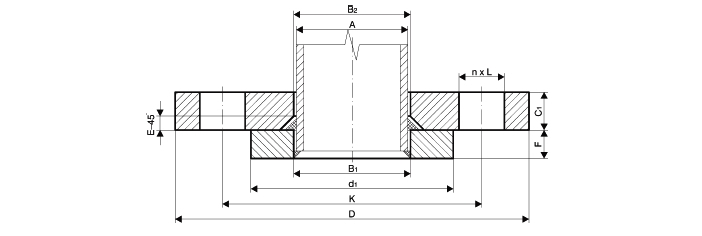

Loose flanges type 02 with flat ring for welding type 32

Technical data

nominal pressure PN 6

| nominal diameter DN | pipe | flange type 02 | screws | ring type 32 | ||||||||||

| A | B2 | D | K | C1 | E | L | weight kg | n | thread | d1 | B1 | F | weight kg | |

| 10 | 13,5* | 17 | 75 | 50 | 12 | 3 | 11 | 0,32 | 4 | M10 | 35 | 14 | 10 | 0,06 |

| 17,2 | 21 | 0,31 | 18 | |||||||||||

| 15 | 20,0* | 24 | 80 | 55 | 12 | 3 | 11 | 0,35 | 4 | M10 | 40 | 20,5 | 10 | 0,07 |

| 21,3 | 25 | 0,35 | 22,5 | |||||||||||

| 20 | 25,0* | 29 | 90 | 65 | 14 | 4 | 11 | 0,54 | 4 | M10 | 50 | 26 | 10 | 0,11 |

| 26,9 | 31 | 0,53 | 27,5 | |||||||||||

| 25 | 30,0* | 34 | 100 | 75 | 14 | 4 | 11 | 0,66 | 4 | M10 | 60 | 32 | 10 | 0,16 |

| 33,7 | 38 | 0,65 | 34,5 | 0,15 | ||||||||||

| 32 | 38,0* | 41 | 120 | 90 | 16 | 5 | 14 | 1,09 | 4 | M12 | 70 | 39 | 10 | 0,21 |

| 42,4 | 46 | 1,05 | 43,5 | 0,19 | ||||||||||

| 40 | 44,5* | 48 | 130 | 100 | 16 | 5 | 14 | 1,27 | 4 | M12 | 80 | 45,5 | 10 | 0,27 |

| 48,3 | 53 | 1,23 | 49,5 | 0,24 | ||||||||||

| 50 | 57,0* | 61 | 140 | 110 | 16 | 5 | 14 | 1,39 | 4 | M12 | 90 | 58 | 12 | 0,35 |

| 60,3 | 65 | 1,35 | 61,5 | 0,32 | ||||||||||

| 65 | 76,1 | 81 | 160 | 130 | 16 | 6 | 14 | 1,70 | 4 | M12 | 110 | 77,5 | 12 | 0,45 |

| 80 | 88,9 | 94 | 190 | 150 | 18 | 6 | 18 | 2,72 | 4 | M16 | 128 | 90,5 | 12 | 0,61 |

| 100 | 108,0* | 113 | 210 | 170 | 18 | 6 | 18 | 3,17 | 4 | M16 | 148 | 109 | 14 | 0,86 |

| 114,3 | 120 | 3,00 | 116 | 0,73 | ||||||||||

| 125 | 133,0* | 137 | 240 | 200 | 20 | 6 | 18 | 4,25 | 8 | M16 | 178 | 135 | 14 | 1,16 |

| 139,7 | 145 | 4,02 | 141,5 | 1,01 | ||||||||||

| 150 | 159,0* | 163 | 265 | 225 | 20 | 6 | 18 | 4,81 | 8 | M16 | 202 | 161 | 14 | 1,28 |

| 168,3 | 174 | 4,42 | 170,5 | 1,01 | ||||||||||

| 200 | 219,1 | 226 | 320 | 280 | 22 | 6 | 18 | 6,47 | 8 | M16 | 258 | 221,5 | 16 | 1,73 |

| 250 | 273,0 | 281 | 375 | 335 | 24 | 8 | 18 | 8,43 | 12 | M16 | 312 | 276,5 | 18 | 2,32 |

| 300 | 323,9 | 333 | 440 | 395 | 24 | 8 | 22 | 11,24 | 12 | M20 | 365 | 327,5 | 18 | 2,88 |

| 350 | 355,6 | 365 | 490 | 445 | 26 | 8 | 22 | 16,07 | 12 | M20 | 415 | 359,5 | 18 | 4,77 |

| 400 | 406,4 | 416 | 540 | 495 | 28 | 8 | 22 | 19,00 | 16 | M20 | 465 | 411 | 20 | 5,83 |

| 450 | 457,0 | 467 | 595 | 550 | 30 | 8 | 22 | 23,62 | 16 | M20 | 520 | 462 | 20 | 7,02 |

| 500 | 508,0 | 519 | 645 | 600 | 30 | 8 | 22 | 25,37 | 20 | M20 | 570 | 513,5 | 22 | 8,30 |

| 600 | 610,0 | 622 | 755 | 705 | 32 | 8 | 26 | 33,46 | 20 | M24 | 670 | 616,5 | 22 | 9,33 |

| 700 | 711,0 | after agreement with the client | 860 | 810 | after agreement with the client | 26 | - | 24 | M24 | 775 | after agreement with the client | after agreement with the client | ||

| 800 | 813,0 | 975 | 920 | 30 | - | 24 | M27 | 880 | ||||||

| 900 | 914,0 | 1075 | 1020 | 30 | - | 24 | M27 | 980 | ||||||

| 1000 | 1016,0 | 1175 | 1120 | 30 | - | 28 | M27 | 1080 | ||||||

| 1200 | 1219,0 | 1405 | 1340 | 33 | - | 32 | M30 | 1295 | ||||||

| 1400 | 1422,0 | 1630 | 1560 | 36 | - | 36 | M33 | 1510 | ||||||

| 1600 | 1626,0 | 1830 | 1760 | 36 | - | 40 | M33 | 1710 | ||||||

| 1800 | 1829,0 | 2045 | 1970 | 39 | - | 44 | M36 | 1920 | ||||||

| 2000 | 2032,0 | 2265 | 2180 | 42 | - | 48 | M39 | 2125 | ||||||

*pipes diameters not provided the norm EN 1092-1:2001 – can be made for special order

nominal pressure PN 10

| nominal diameter DN | pipe | flange type 02 | screws | ring type 32 | ||||||||||

| A | B2 | D | K | C1 | E | L | weight kg | n | thread | d1 | B1 | F | weight kg | |

| for flanges DN 10 to DN 40 dimensions are valid as for pressure PN 40 | ||||||||||||||

| for flanges DN 50 to DN 150 demensions are valid as for pressure PN 16 | ||||||||||||||

| 200 | 219,1 | 226 | 340 | 295 | 24 | 6 | 22 | 8,97 | 8 | M20 | 268 | 221,5 | 20 | 2,81 |

| 250 | 273,0 | 281 | 395 | 350 | 26 | 8 | 22 | 11,42 | 12 | M20 | 320 | 276,5 | 22 | 3,52 |

| 300 | 323,9 | 333 | 445 | 400 | 26 | 8 | 22 | 13,03 | 12 | M20 | 370 | 327,5 | 22 | 4,02 |

| 350 | 355,6 | 365 | 505 | 460 | 28 | 8 | 22 | 19,68 | 16 | M20 | 430 | 359,5 | 22 | 7,55 |

| 400 | 406,4 | 416 | 565 | 515 | 32 | 8 | 26 | 26,69 | 16 | M24 | 482 | 411 | 24 | 9,38 |

| 450 | 457,0 | 467 | 615 | 565 | 36 | 8 | 26 | 32,53 | 20 | M24 | 532 | 462 | 24 | 10,29 |

| 500 | 508,0 | 519 | 670 | 620 | 38 | 8 | 26 | 38,88 | 20 | M24 | 585 | 513,5 | 26 | 12,58 |

| 600 | 610,0 | 622 | 780 | 725 | 42 | 8 | 30 | 52,67 | 20 | M27 | 685 | 616,5 | 26 | 14,28 |

nominal pressure PN 16

| nominal diameter | pipe | flange type 02 | screw | ring type 32 | ||||||||||

| A | B2 | D | K | C1 | E | L | weight kg | n | thread | d1 | B1 | F | weight kg | |

| for flanges DN 10 to DN 40 dimensions are valid as for pressure PN 40 | ||||||||||||||

| 50 | 57,0* | 61 | 165 | 125 | 19 | 5 | 18 | 2,60 | 4 | M16 | 102 | 58 | 16 | 0,69 |

| 60,3 | 65 | 2,54 | 61,5 | 0,65 | ||||||||||

| 65 | 76,1 | 81 | 185 | 145 | 20 | 6 | 18 | 3,09 | 8 | M16 | 122 | 77,5 | 16 | 0,88 |

| 80 | 88,9 | 94 | 200 | 160 | 20 | 6 | 18 | 3,52 | 8 | M16 | 138 | 90,5 | 16 | 1,07 |

| 100 | 108,0* | 113 | 220 | 180 | 22 | 6 | 18 | 4,48 | 8 | M16 | 158 | 109 | 18 | 1,45 |

| 114,3 | 120 | 4,26 | 116 | 1,28 | ||||||||||

| 125 | 133,0* | 137 | 250 | 210 | 22 | 6 | 18 | 5,58 | 8 | M16 | 188 | 135 | 18 | 1,90 |

| 139,7 | 145 | 5,27 | 141,5 | 1,70 | ||||||||||

| 150 | 159,0* | 163 | 285 | 240 | 24 | 6 | 22 | 7,51 | 8 | M20 | 212 | 161 | 20 | 2,34 |

| 168,3 | 174 | 6,96 | 170,5 | 1,96 | ||||||||||

| 200 | 219,1 | 226 | 340 | 295 | 26 | 6 | 22 | 9,41 | 12 | M20 | 268 | 221,5 | 20 | 2,81 |

| 250 | 273,0 | 281 | 405 | 355 | 29 | 8 | 26 | 13,75 | 12 | M24 | 320 | 276,5 | 22 | 3,52 |

| 300 | 323,9 | 333 | 460 | 410 | 32 | 8 | 26 | 18,26 | 12 | M24 | 378 | 327,5 | 24 | 5,27 |

| 350 | 355,6 | 365 | 520 | 470 | 35 | 8 | 26 | 27,25 | 16 | M24 | 438 | 359,5 | 26 | 10,03 |

| 400 | 406,4 | 416 | 580 | 525 | 38 | 8 | 30 | 34,88 | 16 | M27 | 490 | 411 | 28 | 12,28 |

| 450 | 457,0 | 467 | 640 | 585 | 42 | 8 | 30 | 44,91 | 20 | M27 | 550 | 462 | 30 | 16,46 |

| 500 | 508,0 | 519 | 715 | 650 | 46 | 8 | 33 | 62,39 | 20 | M30 | 610 | 513,5 | 32 | 21,38 |

| 600 | 610,0 | 622 | 840 | 770 | 52 | 8 | 36 | 93,82 | 20 | M33 | 725 | 616,5 | 32 | 28,70 |

nominal pressure PN 25

| nominal diameter DN | pipe | flange type 02 | screws | ring type 32 | ||||||||||

| A | B2 | D | K | C1 | E | L | weight kg | n | thread | d1 | B1 | F | weight kg | |

| for flanges DN 10 to DN 150 dimensions are valis as for pressure PN 40 | ||||||||||||||

| 200 | 219,1 | 226 | 360 | 310 | 32 | 6 | 26 | 13,88 | 12 | M24 | 278 | 221,5 | 26 | 4,52 |

| 250 | 273,0 | 281 | 425 | 370 | 35 | 8 | 30 | 19,60 | 12 | M27 | 335 | 276,5 | 26 | 5,73 |

| 300 | 323,9 | 333 | 485 | 430 | 38 | 8 | 30 | 25,74 | 16 | M27 | 395 | 327,5 | 28 | 8,41 |

| 350 | 355,6 | 365 | 555 | 490 | 42 | 8 | 33 | 40,73 | 16 | M30 | 450 | 359,5 | 32 | 14,45 |

| 400 | 406,4 | 416 | 620 | 550 | 46 | 8 | 36 | 54,03 | 16 | M33 | 505 | 411 | 34 | 18,04 |

| 450 | 457,0 | 467 | 670 | 600 | 50 | 8 | 36 | 63,13 | 20 | M33 | 555 | 462 | 36 | 20,98 |

| 500 | 508,0 | 519 | 730 | 660 | 56 | 8 | 36 | 82,00 | 20 | M33 | 615 | 513,5 | 38 | 26,82 |

| 600 | 610,0 | 622 | 845 | 770 | 68 | 8 | 39 | 124,34 | 20 | M36 | 720 | 616,5 | 40 | 34,10 |

*pipes diameters not provided the norm EN 1092-1:2001 – can be made for special order

nominal pressure PN 40

| nominal diameter DN | pipe | flange type 02 | screws | ring type 32 | ||||||||||

| A | B2 | D | K | C1 | E | L | weight kg | n | thread | d1 | B1 | F | weight kg | |

| 10 | 13,5* | 17 | 90 | 60 | 14 | 3 | 14 | 0,61 | 4 | M12 | 40 | 14 | 12 | 0,10 |

| 17,2 | 21 | 0,59 | 18 | 0,09 | ||||||||||

| 15 | 20,0* | 24 | 95 | 65 | 14 | 3 | 14 | 0,66 | 4 | M12 | 45 | 20,5 | 12 | 0,12 |

| 21,3 | 25 | 0,66 | 22,5 | 0,11 | ||||||||||

| 20 | 25,0* | 29 | 105 | 75 | 16 | 4 | 14 | 0,93 | 4 | M12 | 58 | 26 | 14 | 0,23 |

| 26,9 | 31 | 0,91 | 27,5 | 0,22 | ||||||||||

| 25 | 30,0* | 34 | 115 | 85 | 16 | 4 | 14 | 1,11 | 4 | M12 | 68 | 32 | 14 | 0,31 |

| 33,7 | 38 | 1,08 | 34,5 | 0,30 | ||||||||||

| 32 | 38,0* | 41 | 140 | 100 | 18 | 5 | 18 | 1,84 | 4 | M16 | 78 | 39 | 14 | 0,39 |

| 42,4 | 46 | 1,80 | 43,5 | 0,36 | ||||||||||

| 40 | 44,5* | 48 | 150 | 110 | 18 | 5 | 18 | 2,10 | 4 | M16 | 88 | 45,5 | 14 | 0,49 |

| 48,3 | 53 | 2,04 | 49,5 | 0,46 | ||||||||||

| 50 | 57,0* | 61 | 165 | 125 | 20 | 5 | 18 | 2,74 | 4 | M16 | 102 | 58 | 16 | 0,69 |

| 60,3 | 65 | 2,67 | 61,5 | 0,65 | ||||||||||

| 65 | 76,1 | 81 | 185 | 145 | 22 | 6 | 18 | 3,40 | 8 | M16 | 122 | 77,5 | 16 | 0,88 |

| 80 | 88,9 | 94 | 200 | 160 | 24 | 6 | 18 | 4,23 | 8 | M16 | 138 | 90,5 | 18 | 1,20 |

| 100 | 108,0* | 113 | 235 | 190 | 26 | 6 | 22 | 6,18 | 8 | M20 | 162 | 109 | 20 | 1,77 |

| 114,3 | 120 | 5,92 | 116 | 1,58 | ||||||||||

| 125 | 133,0* | 137 | 270 | 220 | 28 | 6 | 26 | 8,41 | 8 | M24 | 188 | 135 | 22 | 2,32 |

| 139,7 | 145 | 8,02 | 141,5 | 2,08 | ||||||||||

| 150 | 159,0* | 163 | 300 | 250 | 30 | 6 | 26 | 10,73 | 8 | M24 | 218 | 161 | 24 | 3,19 |

| 168,3 | 174 | 10,04 | 170,5 | 2,73 | ||||||||||

| 200 | 219,1 | 226 | 375 | 320 | 36 | 6 | 30 | 17,47 | 12 | M27 | 285 | 221,5 | 28 | 5,55 |

| 250 | 273,0 | 281 | 450 | 385 | 42 | 8 | 33 | 28,59 | 12 | M30 | 345 | 276,5 | 30 | 7,87 |

| 300 | 323,9 | 333 | 515 | 450 | 48 | 8 | 33 | 40,50 | 16 | M30 | 410 | 327,5 | 34 | 12,75 |

| 350 | 355,6 | 365 | 580 | 510 | 54 | 8 | 36 | 60,71 | 16 | M33 | 465 | 359,5 | 36 | 19,30 |

| 400 | 406,4 | 416 | 660 | 585 | 60 | 8 | 39 | 88,07 | 16 | M36 | 535 | 411 | 42 | 30,36 |

| 450 | 457,0 | 467 | 685 | 610 | 66 | 8 | 39 | 89,77 | 20 | M36 | 560 | 462 | 46 | 28,39 |

| 500 | 508,0 | 519 | 755 | 670 | 72 | 8 | 42 | 117,75 | 20 | M39 | 615 | 513,5 | 50 | 35,29 |

| 600 | 610,0 | 622 | 890 | 795 | 84 | 8 | 48 | 185,90 | 20 | M45 | 735 | 616,5 | 54 | 53,29 |

*pipes diameters not provided the norm EN 1092-1:2001 – can be made for special order

You may also like:

globe valves

Globe valves are designed for water, steam, oil and other liquids and gases, and acid-resistant performance to the chemically active agents (acids, bases, salt solutions), the range of concentrations of conditioned behavior of materials used in their construction. Are generally used on installations, refineries, pipelines, general purpose industrial and marine pipelines, used to cut off the flow of refrigerant, and in the execution of the fungus control – to throttle the flow.

knife gate valves

Knife gate valves shut off mechanically contaminated liquid media and media flowing, such as pulp. They are mounted both in horizontal and vertical. They can be made with the stem-rising and rising, with manual control with automatic wheel or by using pneumatic or electric actuator. It is possible to building underground. They are used in sewage treatment plants, sewage networks, drainage facilities, stations bulk materials, pulp and paper industry, food processing, brewing, metallurgy, chemical industry.

check valves

Check valves, as a non-return valves, are used to protect piping and equipment against reverse flow of the medium. They are installed on pipelines and tank stationary and transport on the lines of industrial, measuring, and in the installation, where we have to prevent the backflow of stream flow. Check valves are designed for: water, steam, oil and other natural liquids and gases, work in marine, and performed by acid-resistant to chemically active agents.